1. Importance and objectives

Context

As soon as an initiative to improve energy efficiency is launched, it is necessary to be able to quantify a company's energy performance.

Energy accounting is the first tool that should be implemented by companies that want to vastly improve their energy performance. Once established, it will also be able to supply an energy audit with precise and reliable data.

Short-term achievable goals

- Raising awareness: know your energy costs and their impact on the company's operating costs

- Accounting matters: distribute energy costs between different consumers or production lines

- Management: manage the operation with a clear knowledge of energy issues in order to control energy performance

Long-term goals

- To establish its energy performance independently of climatic conditions

- To monitor energy performance against objectives and detect and resolve deviation

- To carry out a comparison between its buildings and operations as well as potentially in relation to other external references

- To establish its energy budget more easily by knowing the key variables

- To monitor the effect of energy efficiency projects (comparison of consumption before/after)

- To establish a fundamental step in the performance of an energy audit and in the introduction of an energy management system

2. Important steps for implementation

Planning

- Make an inventory of the buildings to include.

- Define the periodicity of the monitoring: (daily, weekly or monthly) according to the amount of consumption as well as the means of reading available.

Data collection

Measure or collect data regularly using a precise and consistent method:

- energy consumption of the different departments

- energy purchases

- possible resale of energy outside the company

- renewable energy production

- adjustment parameters: climatic factors or degree days (non-residential buildings)

- production (useful effect of a manufacturing company)

Data processing

Enter the data into a spreadsheet or specialised software.

- Standardise: the data collected is expressed in different forms (litres of fuel, tonnes of fuel, m3 of gas, etc.): it is essential to convert all energy purchases and breakdowns into standard energy units (e.g. kWh)

- Distribute consumption between the different sub-assemblies.

The information obtained at this stage allows an accounting breakdown of energy consumption to be made. However, it is not yet ready for practical use: depending on the level of company activity or on climatic factors, they still need to be "normalised" as explained below.

3. Results – Buildings

Use of results – Administrative buildings

Using the data correctly can tell you a lot about how energy is used. As such, it will make the time invested worthwhile.

Normalisation:

This operation cancels out the effect of climatic variations by expressing the observed situation in relation to a reference situation.

In Luxembourg, the Energy Performance Certificate includes this correction in its calculation method. The corresponding climate correction factors are defined annually by ministerial regulations.

For internal purposes, an alternative method based on degree days can be used for a usage not subject to the regulations on the energy performance of buildings.

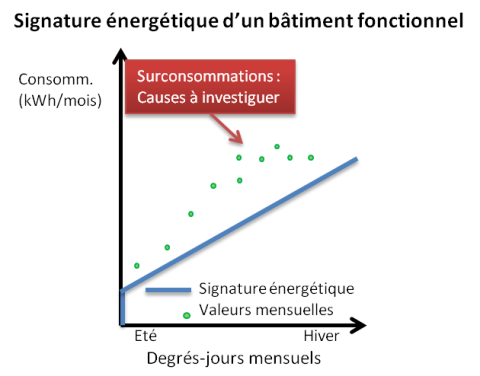

Energy signature of the building:

This is a visual representation of the observed energy consumption as a function of climatic variations (Degree Days). It is based on observations of several heating periods and makes it possible to detect deviation: points deviating from the "tolerance zone" can indicate inadequate heating behaviour.

Towards development of the building energy performance register:

The resulting dataset is an important source of data in the context of an energy audit, the first step in a project to improve the energy efficiency of the building stock.

Energy signature of a non-residential building

Consumption (kWh/month)

Monthly values

Monthly degree days

Summer

Winter

Overconsumption: reasons to be investigated

4. Results – Industry

Use of results – Industry

In the industrial sector, energy performance depends very little on climatic factors or the energy consumption of administrative buildings. On the contrary, it depends mainly on factors relating to the activity of the company: manufactured or transformed products are the most common factors encountered in industry.

Simple cases: uniform products

In the simplest cases, it is customary to describe consumption in relation to the volume of activity: specific energy consumption (SEC) is defined as the ratio of net energy consumption to physical output, e.g. in kWh per kg of finished product.

More complex cases:

Obtaining a single value for specific energy consumption is sometimes unrepresentative of the real efficiency of the company because it is too simplistic. Real cases must be assessed using a more precise method because:

- the specific consumption of each product or group of products can be very different: its distribution between the volumes of the different products must be taken into account

- a single specific consumption indicator is impossible to achieve if the products are produced in different physical forms (sheets, bars, threads, liquid, gas, etc.)

- the contribution of buildings and other utilities to overall energy consumption can be significant and must sometimes be taken into account

The solution is to calculate a weighted Energy Efficiency Index (EEI) based on all of this data.

Next, a graphical representation will help to diagnose the energy performance of the company (see below).

Industry: Representation based on production levels

Consumption (kWh/month)

Production (tonnes/month)

Overconsumption

Deposits of potential?

Reference consumption

Monthly values

Acceptable limit

Existence of optimum production levels?

5. Practical aspects

Automation of operations

Designing a measurement system is often considered a “luxury” that does not provide short-term benefits. The measuring equipment is expensive, implementation is complex and measurement campaigns do not offer a sufficient return on investment.

However, effective energy management cannot exist without the energy performance measurement function; similarly, an energy management system (e.g. according to the ISO 50001 standard) cannot function in the absence of reliable and representative measurements of the activity.

Reading meters and exploiting the results is time-consuming: this is an area where automation can save you time.

Smart meters

European legislation requires Distribution System Operators (DSOs) to provide intelligent metering systems that allow users to measure their energy consumption accurately at all times.

Energy accounting software

The range of suitable software and systems on the market is abundant, so each user can find a product that meets their needs.

Meter reading services

Specialised companies offer meter reading services, e.g. for reinvoicing building tenants (facility management). The arrival on the market of automatic reading systems reduces labour costs, thus keeping these services affordable and professional.

Example: the voluntary agreement

Energy-intensive Luxembourg companies that have decided to join this programme monitor and report, among other things, annually on their progress in terms of energy efficiency. To do this, they have developed energy efficiency indices based on their specific consumption. This monitoring allows them to check their progress towards the target and to verify the effect of the energy efficiency measures implemented.

This document is intended for information and to raise awareness. The information and values herein are provided for information only and must be verified by a professional before any decision is made. Klima-Agence declines all responsibility in the event of inappropriate use of its contents.